Composite materials

What is a composite material?

Composite materials are solid materials made through the association of several materials with complementary characteristics (fibreglass + polyester resin, for example).

This association gives them a number of properties- mechanical, chemical etc. – which they would not possess individually.The main constituents are the reinforcement (fibreglass, carbon, Kevlar etc.) and the matrix (polyester resin, epoxy, vinyl ester etc.).

The purpose of the reinforcement is to support most of the mechanical load applied to the composite material.

The role of the matrix (or binder) is to bind the reinforcements together, protect them from the external environment (corrosion, chemical agent, for example) and distribute the mechanical load applied.

What are the benefits of a composite material?

- Rigid (more rigid than steel)

- Mechanical resistance

- Long-lasting, resistant to fatigue

- Hermetic

- Resistant to chemical agents

- Resistant to corrosion

- Free-form

- Dimensional control

- Provides electrical, thermal and/or acoustic insulation

- Impact – resistant

- Fire – resistant

- Possibility of incorporating a functional option (hinge, electric wiring, all kinds of insert etc.)

- Body-tinted

The main components

Fibreglass

✓ Good performance/price ratio

✓ Available in all shapes

✓ Adheres well to all resins

✓ Temperature-resistant

✓ Low rate of thermal expansion

✓ Good dielectric properties

✓ Good resistance to moisture

✓ Most common reinforcement used for industrial applications

Applications: transport, industry, sport & leisure, construction, medical, energy, automobile, etc.

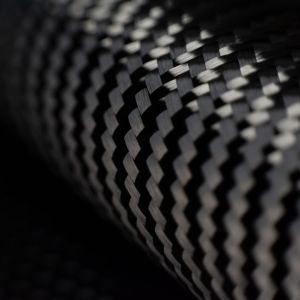

Carbon fibre

✓ Excellent mechanical properties

✓ Good resistance to temperature

✓ Zero thermal expansion

✓ Good machinability

✓ Good thermal and electrical conductibility

✓ Excellent resistance to moisture

✓ Low impact resistance

Applications: aeronautics, defence, industry, transport, automobile, sport & leisure etc.

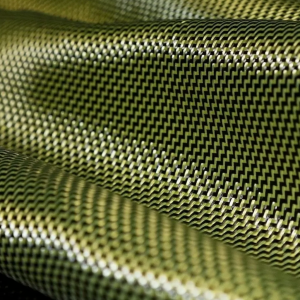

Kevlar (Aramide)

✓ Very good resistance to tensile stress

✓ Zero thermal expansion

✓ Excellent vibration absorption

✓ Very good resistance to impact and fatigue

✓ Low density

✓ Often used in the defence sector

Applications: aeronautics, defence etc.

Resins

✓ Polyester

✓ Vinyl ester

✓ Epoxy

✓ Polyurethane

✓ Silicon

N.B. This is not a complete list of the reinforcements and resins used at Sobelcomp

Comparison of the characteristics of composite materials and metals

| Features | Metals | Composites with organic matrices (1) | |||||

|---|---|---|---|---|---|---|---|

| 35 NCD 16 Steel | AU 4 SG Aluminium Alloy | TA 6 V Titanium Alloy | HR Carbon/epoxy resin | HM Carbon/epoxy resin | Aramid/epoxy resin | R Glass /epoxy resin | |

| Tensile characteristics: | |||||||

| Tensile strength R(MPa) | 1850 | 500 | 1000 | 1000 to 1300 | 1000 | 1300 to 1800 | 1800 to 2000 |

| Young’s modulus E (GPa) | 200 | 72 | 110 | 130 | 200 | 75 | 53 |

| Density ᵨ(g/cm³) | 7.9 | 2.8 | 4.45 | 1.5 | 1.7 | 1.37 | 2 |

| Breaking strength R/ᵨg (km) | 24 | 18 | 23 | 65 to 85 | 60 | 95 to 130 | 90 to 100 |

| Young’s modulus E/ᵨg (km) | 2500 | 2600 | 2500 | 8700 | 11800 | 5500 | 2650 |

| Coefficient of linear expansion(K-1): | |||||||

| Longitudinal | 12 – 10-6 | 23 – 10-6 | (2) | -0.2 – 10-6 | -0.8 – 10-6 | -5 – 10-6 | 6 – 10-6 |

| Transverse | 12 – 10-6 | 23 – 10-6 | (2) | 35 – 10-6 | 35 – 10-6 | 60 – 10-6 | 31 – 10-6 |

(1) Unidirectional composites with 60% fibre volume

(2) Values unknown by author

g acceleration due to weight

According to A. Négrier and J.C. Rigal